Components in the Circuit:

- Solar panel

- ATmega8 micro controller

- Light Dependent Resistor.

- Motor driver IC

- Stepper Motor.

![]()

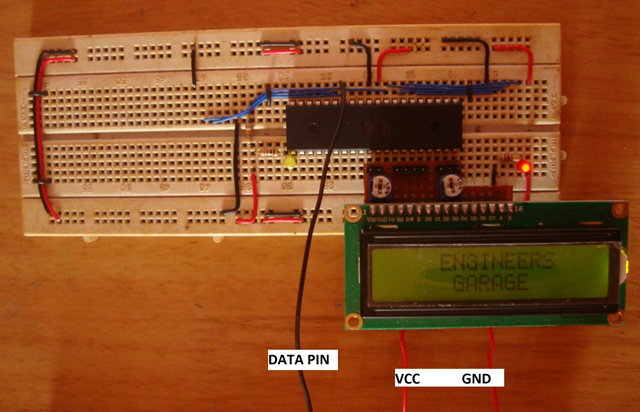

Automated Sun Tracking Solar Panel Circuit Design:

The proposed system consists of ATmega8 micro controller, Solar panel, Light Dependent resistors and motor driver IC.

ATmega8 is AVR family micro controller. It is based on advanced RISC architecture. It is an 8 bit controller. It has 4KB Flash memory, 512 bytes of EEPROM and 1Kb of SRAM. It has 23 programmable pins. It supports peripheral features like two 8-bit timers, one 16 bit timer, 6 channel ADC with 10-bit resolution, programmable USART, Serial peripheral interface, 2 wire serial interface, etc.

Solar panel is connected to Stepper motor. Solar panel consists of photovoltaic cells arranged in an order. Photovoltaic cell is nothing but a solar cell. Photo resembles light and voltaic is electricity. Solar cell is made up of semiconductor material silicon. When a light ray from Sun is incident on the solar cell, some amount of energy is absorbed by this material. The absorbed energy is enough for the electrons to jump from one orbit to other inside the atom. Cells have one or more electric field that directs the electrons which creates current. By placing metal contact energy can be obtained from these cells.

Light Dependent Resistors are the resistors whose resistance values depend on intensity of the light. As the intensity of light falling on the LDR increases, resistance value decreases. In dark, LDR will have maximum resistance. LDR will output an analog value which should be converted to digital. This can be done using analog to digital converter. ATmega8 has analog to digital converter internally. It has six ADC channels from ADC0 to ADC5.The two LDRs are connected to ADC pins i.e. PC0 and PC1. ADC conversion is done using successive approximation method.

Stepper motor rotates the panel in a stepwise angle. To drive this motor a driver IC is used. Driver IC amplifies the input voltage and protects the microcontroller from back EMF. Generally, motors generate back EMF. This may damage the controller. The driver IC used is L293D. It has H bridge internally made up of transistors. This IC has 16 pins. Output pins are connected to the stepper motor pins. Input pins are connected to the controller pins as shown in circuit diagram.

By connecting a battery to the solar panel, one can store the energy generated by the solar cells and this energy can be used when required.

You must be logged in to post a comment.